Grinding Stainless Steel: The Ultimate Guide

Stainless steel is a versatile and durable material used in a variety of industries, including but not limited to automotive, aerospace, and medical. During the manufacturing process, it undergoes multiple stages, including cutting, shaping, welding, and polishing. One of the most crucial stages is grinding, which plays a vital role in enhancing the material's final appearance, functionality, and longevity. However, grinding stainless steel is not as straightforward as it might seem. It requires the right approach, tools, and techniques to achieve the desired results. In this article, we will explore the various aspects of grinding stainless steel, including its benefits, challenges, methods, and safety precautions.

Benefits of Grinding Stainless Steel

Grinding stainless steel offers numerous benefits, including:

- Improves Surface Finish: Stainless steel is known for its high luster and smooth surface finish. Grinding helps to remove any imperfections, scratches, or blemishes and create a uniform surface that enhances its aesthetic appeal.

- Enhances Corrosion Resistance: Stainless steel is resistant to rust and corrosion due to the presence of chromium. However, during the machining process, it may develop surface contaminants or burrs that can compromise its corrosion resistance. Grinding helps to remove these surface defects, improving the material's overall durability and longevity.

- Increases Wear Resistance: Stainless steel is often used in high-wear applications, such as gears, bearings, and cutting tools. Grinding can increase the material's hardness, making it more resistant to wear and tear.

Challenges of Grinding Stainless Steel

While there are many benefits to grinding stainless steel, there are also several challenges that need to be considered, including:

- Toughness: Stainless steel is a hard and tough material, which means that it takes longer to grind compared to softer materials.

- Heat Build-up: Grinding generates heat, which can distort the material's shape and alter its properties. This can be especially problematic with stainless steel, as overheating can lead to carbide precipitation, which can weaken the material's corrosion resistance.

- Clogging: Stainless steel has a tendency to clog the grinding wheels. This can lead to reduced efficiency and productivity, as well as safety hazards.

Methods of Grinding Stainless Steel

There are various methods of grinding stainless steel, each with its advantages and disadvantages. The most common methods are:

- Surface Grinding: Surface grinding involves using a grinding wheel to create a flat and smooth surface on a workpiece. This method is ideal for removing large amounts of material and achieving a high degree of accuracy and precision. However, it can generate significant heat and may not be suitable for thinner materials.

- Centerless Grinding: Centerless grinding involves feeding a workpiece through two rotating wheels, one of which is an abrasive grinding wheel. This method is ideal for producing cylindrical or spherical parts with a high degree of accuracy and repeatability. However, it requires specialized equipment and may not be suitable for all types of materials.

- Blanchard Grinding: Blanchard grinding is a method of surface grinding that uses a rotary table and a grinding wheel to remove material from a workpiece. This method is ideal for larger parts and can achieve a high degree of parallelism and flatness. However, it requires specialized equipment and may not be suitable for thinner materials.

- Safety Precautions for Grinding Stainless Steel

- Grinding stainless steel can be dangerous if proper precautions are not taken. Some of the safety measures that should be observed include:

- Wear Protective Gear: When grinding stainless steel, it is essential to wear appropriate protective gear, including safety glasses, gloves, and respiratory protection.

- Use Adequate Ventilation: Grinding generates dust and fumes that may be harmful if inhaled. It is important to use adequate ventilation or wear a respirator to avoid respiratory problems.

- Keep the Work Area Clean and Organized: Cluttered work areas increase the risk of accidents and injuries. Keep the area clean and organized to avoid tripping hazards and other safety issues.

Conclusion

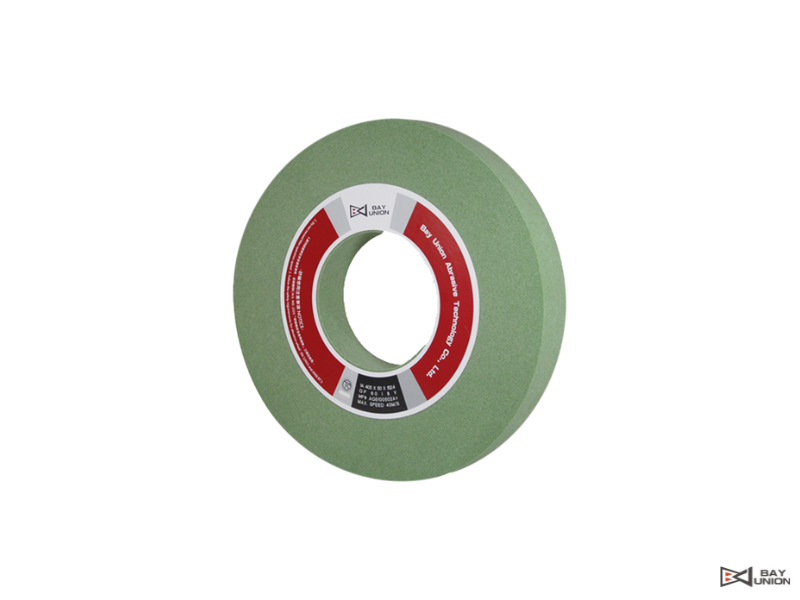

Grinding stainless steel is an essential part of the manufacturing process that requires skill, knowledge, and attention to detail. It offers numerous benefits, including improving surface finish, enhancing corrosion resistance, and increasing wear resistance. However, it also comes with its challenges, including its toughness, heat build-up, and clogging. By using the right methods and safety precautions, grinding stainless steel can be a safe and efficient process that produces high-quality results. As a leading grinding wheels manufacturer in Taiwan, BAY UNION offers a wide range of high-quality abrasive solutions and technical expertise to help customers achieve their grinding objectives.