Comprehensive Introduction to Surface Grinding Wheels by Bay Union

Introduction

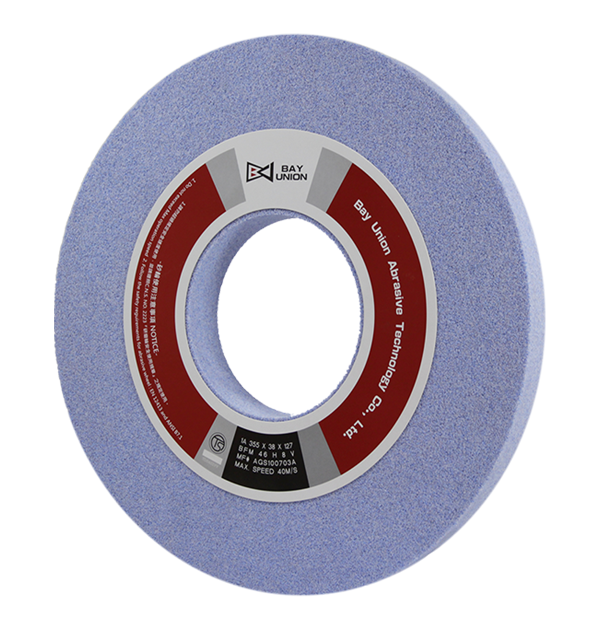

Bay Union Abrasive Technology Co., Ltd. is proud to present our expertly crafted surface grinding wheels, pivotal in shaping and finishing metals with unmatched precision. These tools are engineered for a variety of industrial applications, each designed to meet rigorous performance and quality standards. As leaders in abrasive technology, our focus remains on delivering products that enhance efficiency and quality in all your grinding projects.

What is a Surface Grinding Wheel?

A surface grinding wheel is a sophisticated tool comprising bonded abrasive grains. It's utilized in grinding machines to achieve smooth and precise finishes on flat surfaces. The wheel actively removes small material chips from the workpiece, enhancing both the smoothness and precision of the final product.

Characteristics and Types

Surface grinding wheels vary extensively to accommodate different materials and machining requirements. Key characteristics include:

- Abrasive Material: Determines the aggressiveness and durability of the wheel.

- Grain Size: Impacts the finish quality and material removal rate.

- Bond Type: Influences the wheel’s strength and the rate at which the abrasives are shed.

- Wheel Grade: Affects the hardness of the grinding wheel which in turn controls its cutting ability.

These factors collectively define the wheel's suitability for tasks ranging from rough grinding to precision finishing, adapting to various industrial demands.

Maintenance and Safety Tips

- Routine Maintenance Checks: Regular inspections are critical to detect any signs of wear or damage that could compromise the wheel's integrity. Look for cracks, unusual wear patterns, or changes in shape that could indicate a need for replacement.

- Proper Storage Practices: Ensure that grinding wheels are stored in a cool, dry environment away from direct sunlight and temperature fluctuations. Stacking the wheels horizontally, supported by cushioning materials, prevents warping and damage.

- Adherence to Operational Guidelines: Follow the manufacturer's recommendations for speed settings and operational limits to ensure safety and prevent overloading the wheel. Always ensure the wheel is properly mounted and securely fastened before use.

- Use of Safety Gear: Operators should always wear appropriate personal protective equipment (PPE) such as safety glasses, face shields, and gloves. Ensure all safety guards are in place on the grinding machinery to protect against debris and sparks.

- Training and Awareness: Regular training sessions for staff on the correct handling and usage of grinding wheels can drastically reduce the risk of accidents. This includes training on emergency procedures and first aid.

By adhering to these maintenance and safety protocols, the lifespan and effectiveness of surface grinding wheels can be maximized, ensuring safe and efficient operation.

Technological Innovations

Bay Union continually invests in the development of new abrasive materials and bonding techniques to enhance the performance and range of applications for our grinding wheels. These innovations lead to improved productivity, precision, and adaptability across various industries.

Categories of Surface Grinding Wheels

- General Steel Wheels (BF Series): These wheels are designed for general steel and alloys with hardness between HRc40 and HRc60, offering a longer wheel lifetime.

- Harder Alloys Wheels (CK Series): Specifically for harder materials such as STAVAX, SKH, and SKD over HRc55, these wheels use a blend of special abrasives to enhance grinding capabilities.

- Specialized Applications: Tailored for specific needs like precision automotive parts and intricate tools, addressing unique material properties and performance requirements.

Industry Applications of Surface Grinding Wheels

- Automotive Industry: Essential for manufacturing and finishing parts like gears, pistons, and other components requiring precise dimensions and smooth surfaces.

- Aerospace Sector: Used in the production and maintenance of aircraft components, where exact tolerances and finishes are critical for safety and performance.

- Electronics Manufacturing: Applied in the creation of components where high precision is necessary to ensure functionality and reliability, such as semiconductor parts and PCBs.

Case Study: Bearing Industry

Bay Union has successfully implemented its EB series surface grinding wheels in the bearing industry, specifically for grinding stainless steel components like slide rails and sliders. The EB series has shown remarkable efficiency and smooth operation in machining stainless steel, a material traditionally challenging to grind. This success has led to significant customer satisfaction and subsequent orders.

Conclusion

At Bay Union, we are committed to excellence and innovation in the design and manufacture of surface grinding wheels. Our extensive range of products ensures that whatever your grinding needs, we have a solution that provides the precision, durability, and performance required. With a focus on customer satisfaction and technological advancement, Bay Union remains your trusted partner in abrasive technology. Explore our offerings and see how our expertise can enhance your production processes.

For further information, inquiries, or to discuss your specific abrasive needs, don't hesitate to contact us. Our expert team is ready to provide you with the best solutions and support.