Gear Grinding Wheels

Gear grinding is a precision machining process commonly applied in mechanical manufacturing and industrial fields. Gears are integral components in mechanical transmission systems, and their precision and surface quality directly impact the operational efficiency and performance of machinery.

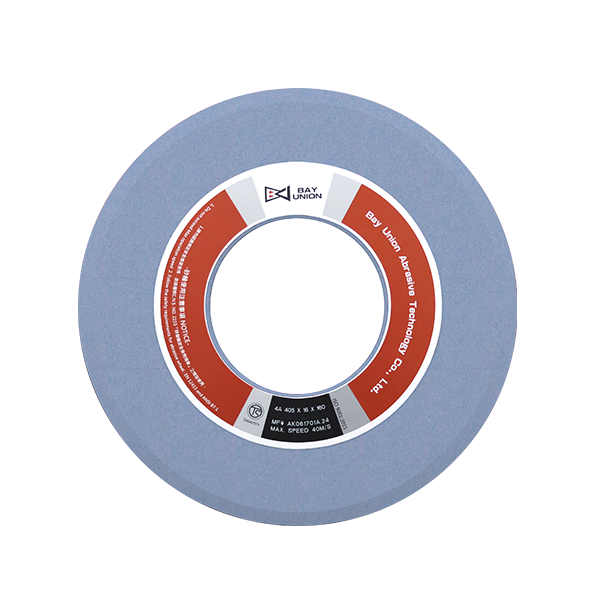

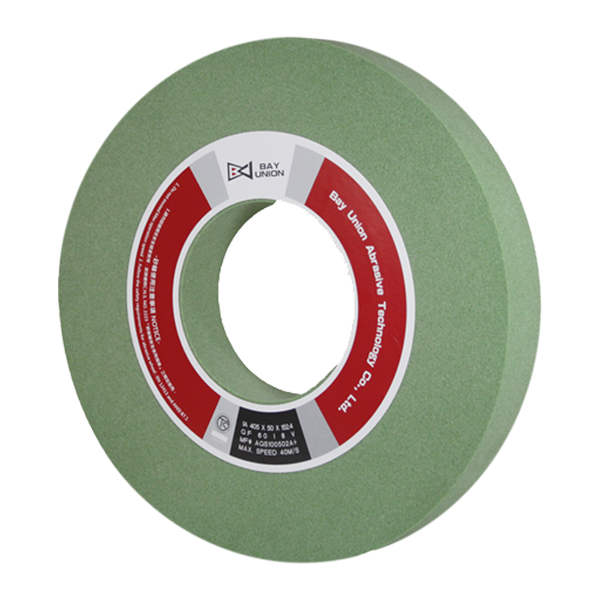

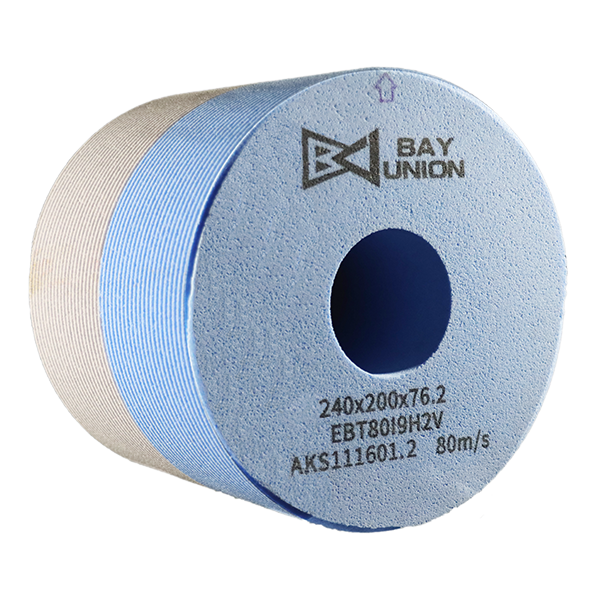

Gear grinding typically requires the use of high-quality grinding wheels with abrasives that offer both high cutting ability and shape retention. This ensures the gears' surfaces are processed to be exceptionally smooth and fine. Simultaneously, during the gear grinding process, it's crucial to strictly control temperature, pressure, and the contact force between the grinding tool and the workpiece to prevent excessive heat deformation and damage.

In the grinding process, selecting suitable grinding wheels, grinding fluids, and grinding parameters is essential to meet the required precision and surface quality of gears. In recent years, with the emphasis on the quiet operation of electric vehicles, there is an increased demand to enhance surface smoothness and precision, thereby reducing friction and energy loss during gear operation, ultimately improving the range and endurance of electric vehicles.

Gear grinding typically requires the use of high-quality grinding wheels with abrasives that offer both high cutting ability and shape retention. This ensures the gears' surfaces are processed to be exceptionally smooth and fine. Simultaneously, during the gear grinding process, it's crucial to strictly control temperature, pressure, and the contact force between the grinding tool and the workpiece to prevent excessive heat deformation and damage.

In the grinding process, selecting suitable grinding wheels, grinding fluids, and grinding parameters is essential to meet the required precision and surface quality of gears. In recent years, with the emphasis on the quiet operation of electric vehicles, there is an increased demand to enhance surface smoothness and precision, thereby reducing friction and energy loss during gear operation, ultimately improving the range and endurance of electric vehicles.